Product Introduction

Scroll down

Measurement SYSTEM

We are developing, manufacturing, and supplying measuring/inspection systems

that achieve quality enhancement, productivity increase, and cost reduction through precise

and effective data collection and analysis in various industries.

Applying optimized solutions such as contact, contactless, optical, non-disruptive, and eddy current,

we provide reliable data to support our customers’ success.

Measurement SYSTEM

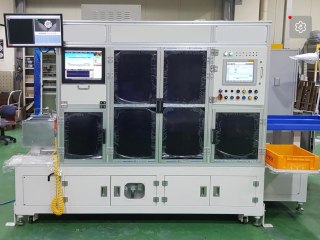

SCREW SPINDLE MEASUR'G MC

MEASUREMENT OF THE OUTER DIAMETER AND LENGTH OF THE SCREW SPINDLE ELEMENT, AND VISUAL INSPECTION OF THE SCREW

Characteristics

- FULL AUTOMATIC SYSTEM

- LIFT & CARRY TRANSFER : AIR CYLINDER

- MEASUR'G STATION : PROBE

- INSPECTION STATION : VISION

- INPUT HOPPER CARRIAGE : 500EA

- OUTPUT CHUTE : 200EA

- DATA TRACK'G MANAGEMENT & DISPLAY

- STATISTICAL PROCESS & QUALITY CONTROL (SPC)

Items for Measurement : DIAMETER, LENGTH, PARALLELISM, FLATNESS, SQUARENESS

DIMENSION REPEATABILITY : ≤ 0.001㎜ (EVALUATED ON THE MASTER)

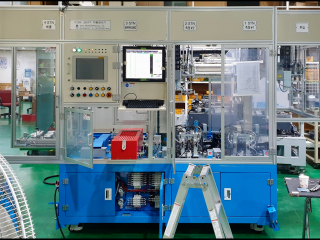

CONROD MEASUR'G MC

MEASUREMENT OF THE DIAMETER, CYLINDRICITY, BENDING, TWIST, PITCH, AND WEIGHT OF THE CONROD ELEMENT

Characteristics

- FULL AUTOMATIC SYSTEM

- PICK & PLACE TRANSFER : SERVO MOTOR

- MEASUR'G STATION : 4SET (MEA. CELL + PROBE + LOADCELL)

- AUTO ZERO MASTER

- INPUT WORK'G CONVEYOR : 200EA (AIR BLOW)

- OUTPUT STOKER : 200EA

- QR CODE MARK'G & READ'G

- DATA TRACK'G MANAGEMENT & DISPLAY

Items for Measurement : DIAMETER, CYLINDRICITY, BENDING, TWIST, PITCH, WEIGHT

DIMENSION REPEATABILITY : ≤ 0.001㎜ (EVALUATED ON THE MASTER)

GEOMETRIC DIMENSION REPEATABILITY : 20% OF TOLERANCE

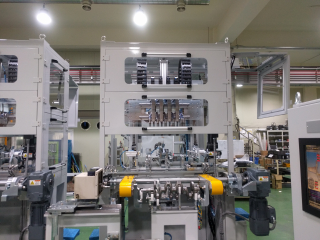

DCT MISSION FORK MEASUR'G MC

MEASUREMENT OF THE INNER DIAMETER, DISTANCE, AND THICKNESS OF THE DCT MISSION FORK ELEMENT

Characteristics

- FULL AUTOMATIC SYSTEM

- PICK & PLACE TRANSFER : AIR, HYDRAULIC CYLINDER

- MEASUR'G STATION : 2SET (MEA. CELL)

- NG CHUTE : 10EA-OCR MARK'G

- DATA TRACK'G MANAGEMENT & DISPLAY

- STATISTICAL PROCESS & QUALITY CONTROL (SPC)

Items for Measurement : DIAMETER, CENTER DISTANCE, THICKNESS, SURFACE DISTANCE

DIMENSION REPEATABILITY : ≤ 0.001㎜ (EVALUATED ON THE MASTER)

TIMMING CHAIN COVER MEASUR'G MC

MEASUREMENT OF THE DIAMETER, HEIGHT, FLATNESS, AND POSITION OF THE TIMMING CHAIN COVER ELEMENT

Characteristics

- SEMI AUTOMATIC SYSTEM

- SHUTTLE TRANSFER : AIR CYLINDER

- MEASUR'G STATION : MEA. CELL + PROBE

- OK PUNCH MARK'G

- NG STORAGE : 1EA

- DATA TRACK'G MANAGEMENT & DISPLAY

- STATISTICAL PROCESS & QUALITY CONTROL (SPC)

Items for Measurement : DIAMETER, HEIGHT, FLATNESS, POSITION

DIMENSION REPEATABILITY : ≤ 0.001㎜ (EVALUATED ON THE MASTER)

GEOMETRIC DIMENSION REPEATABILITY : 20% OF TOLERANCE

CRANK SHAFT CRACK INSPECTION MC

CRACK INSPECTION OF THE CRANK SHAFT ELEMENT

Characteristics

- FULL AUTOMATIC SYSTEM

- SWING ARM TRANSFER : WORM GEAR MOTOR

- INSPECTION STATION : CRACK SENSOR

- AUTO CRACK SETTING MASTER

- DATA TRACK'G MANAGEMENT & DISPLAY

- STATISTICAL PROCESS & QUALITY CONTROL (SPC)

Items for Measurement : JOURNAL, PIN, AND FLANGE CRACK

CRACK MAX SIZE : 3.0㎜ × 0.1㎜ × 0.1㎜ 3.0V NG