Product Introduction

Scroll down

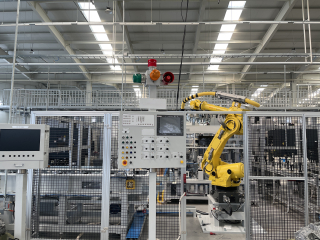

Automation SYSTEM

We are developing, manufacturing, and supplying a system that automates the control, management,

and operation of production by integrating various processes such as mechanization, robotization, and automatic transport in a manufacturing line.

Through this, we support the success of our customers by enhancing production efficiency.

Automation SYSTEM

BEARING PROCESS CLEAN'G LINE

DE-OILING AND CLEANING, AIR BLOW, AND LOGISTICS CONNECTION FOR THE BEARING MACHINING LINE

Characteristics

- FULL AUTOMATIC SYSTEM

- SLIDE & CARRY TRANSFER

- CLEAN & DIRTY TANK CAPACITY: 230L EACH

- OIL MIST CLEANER: 1.5kW, 20㎥/min

- DETERGENT: WHITE KEROSENE

MECAHANICAL LASH ADJUSTER ASSEMBLY LINE

CAMSHAFT, HEAD MEASUREMENT AND CLEARANCE DETERMINATION MLA SELECTION ASSEMBLY

Characteristics

- FULL AUTOMATIC SYSTEM

- PROCESS CONNECTION: FRICTION ROLLER PALLETE CONVEYOR

- HEAD BOLT & WASHER INSERT INSPECTION MC

- HEAD AIR BLOW & CAMSHAFT MODEL CHECK

- CAMSHAFT MEASUR'G MC

- HEAD MEASUR'G MC & OIL SPRAY MC

- MLA INSERT & RECHECK

EV MOTOR HOUS'G PROCESS LINE

INLINE CMM MEASUREMENT, INSPECTION, AND STACKING PROCESS LOGISTICS CONNECTION FOR THE REAR COVER MACHINING LINE

Characteristics

- FULL AUTOMATIC SYSTEM

- PROCESS CONNECTION: 6-AXIS ROBOT

- COOL DOWN & IDLE BUFFER

- NG OUTPUT CONVEYOR : 5EA

- QR CODE READ'G & TRACK'G

- STATISTICAL PROCESS & QUALITY CONTROL (SPC)

EV MOTOR HOUS'G PROCESS LINE

INLINE CMM MEASUREMENT AND INSPECTION PROCESS LOGISTICS CONNECTION FOR THE EV MOTOR HOUS'G MACHINING LINE

Characteristics

- FULL AUTOMATIC SYSTEM

- PROCESS CONNECTION: 6-AXIS ROBOT , ATTACH CHAIN CONVEYOR

- NG OUTPUT CONVEYOR : 5EA

- INSTALLATION OF SELF-INSPECTION TABLES

- QR CODE READ'G & TRACK'G

- STATISTICAL PROCESS & QUALITY CONTROL (SPC)